2020 Annual Report

A Year Like No Other.

“This year has definitely come with its challenges, but FAPC and the food industry moved steadily through 2020. FAPC continued to support food processors and serve as a resource for the industry.”

- Highlights and Impacts

FAPC and the Oklahoma food industry moved steadily through 2020. FAPC continued to support product development, food processing and sensory evaluations through on-site at FAPC and virtual venues as appropriate for the client needs. Workshops were minimized, but they continued with small numbers of participants in each to comply with social distancing and COVID personal hygiene accepted practices.

However, the harvest of beef in FAPC’s second floor abattoir (an essential facility) was increased to help meet the demands of this industry. FAPC immediately put in place campus, state and Centers for Disease Control and Prevention regulations for human contact, social distancing, wearing of protective face masks, separation of employees during work in harvest and processing, and personal hygiene. The FAPC team learned and continued to relearn work habits using the COVID personal protection procedures and used plenty of sanitizing stations.

When there was knowledge that a potential COVID-positive contact was made, quarantine procedures were taken, COVID tests were performed and no one came back to work unless determined COVID negative.

The center’s work base was undergraduate students under the able leadership of Brandon Kahle, FAPC pilot plant manager, and Jake Nelson, FAPC facility manager.

In all, 2020 has been a busy and productive year, and FAPC continued to serve the food processing industry in Oklahoma, having an impact of nearly $6.5 million in sales.

- Year in Review

- Client Projects - 95

- Towns/Cities Represented - 60

- Counties Represented - 45

- Journal Articles and Books/Chapters - 26

- Theses/Dissertations Published - 5

- Education and Training Events - 37

- Education and Training Attendees - 285

- Visitor Sessions/Tours - 70

- Visitors - 1,071

- Trade and Business Shows - 20

- Process Authority Letters Issued - 51

- Nutrition Label Sets Issued - 58

- Grants Submitted - 24

- Food Safety Clients Assisted - 48

- Livestock Harvested and Processed - 259 (171 Beef, 61 Hogs, 27 Lamb/Goats)

- Media & Communications Publications - 363

- Donors

FAPC established a Foundation Focus Program to enable the center to accomplish its mission with increased financial support from private donors, which can include monetary donations as well as in-kind gifts of equipment. Because of this public-private partnership, FAPC is able to focus on delivering even greater economic impact to Oklahoma as it continues to serve the state’s value-added agricultural industry. FAPC would like to recognize the following 2020 donors:

- Dani Bellmer

- Tim Bowser

- Jim Brooks

- Terra Brown

- Lupe Davila-El Rassi

- Nurhan Dunford

- Roy Escoubas

- Delores and Robert Gilliland

- Andrea Graves

- Mandy Gross

- Rodney Holcomb

- David Howard/Howard Enterprises, LLC

- Joyce Hufford

- Integrity Biologics, LLC

- Divya Jaroni

- Erin Johnson

- La Tanja Johnson

- Sheary Johnson

- Tina and Greg Johnson

- Pal Kalyanaraman

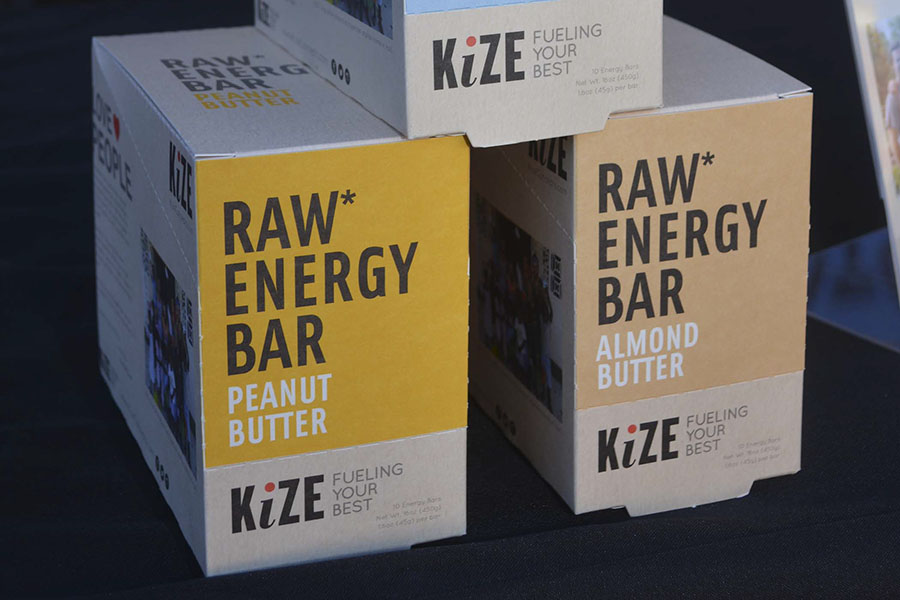

- Kize Concepts

- Angie Lathrop

- Log10 LLC

- Lopez Foods

- Marel

- Christie McComas

- William McGlynn

- Jake & Reneé Nelson

- Patricia Rayas-Duarte

- Karen Smith

- Stillwater Centennial Rotary Club

- Derek and Brenita Walker

- Chuck and Susan Willoughby

- Giving Back

FAPC takes an active role in helping with community efforts such as the annual Stillwater United Way Campaign and food donations to the Regional Food Bank of Oklahoma. In 2020, FAPC raised more than $5,500 for the United Way of Payne County through fundraising events and employee payroll deduction.

FAPC also had the honor to be a key partner to the Oklahoma Pork Council, joining them in their effort to help feed needy Oklahomans. During the COVID-19 pandemic, limited processing capacity led to the potential of euthanizing swine ready for market. FAPC was able to facilitate the harvest and processing of 24 hogs, which were provided by the Oklahoma Pork Council. From these animals, more than 2,500 pounds of fresh ground pork were provided to the Regional Food Bank of Oklahoma.

Additionally, FAPC partnered with the Cactus Cares Foundation in November to sponsor a donation of more than 1,000 pounds of various meats to Stillwater’s Our Daily Bread, an agency of the Regional Food Bank of Oklahoma. A cash donation of $125.25 also was provided by FAPC employees as part of their annual Christmas celebration.

Prior to these opportunities to serve, FAPC had provided more than 8,000 pounds of meats and other food products to the Food Bank since receiving approval from the Board of Regents for the Oklahoma Agricultural & Mechanical Colleges in April 2009.

Featured Projects

- Facilities and Equipment for Food Processing - Producing the First-ever USDA-inspected Edible Cow Skin

The year 2020 has proved that agriculture does not stop, even for a worldwide pandemic. Despite the spread of COVID-19 and the shutdown of Oklahoma State University in the spring and summer of 2020, work at FAPC continued, especially in the pilot plant.

FAPC was heavily utilized in 2020 to not only help with the demand for processing local cattle but also in producing the first-ever United States Department of Agriculture-inspected edible cow skin.

Entrepreneur and owner Siewe Siewe Siewe of KandaKpomo Inc. in Stillwater, Oklahoma, has been working with FAPC to turn local cattle hides from landfill waste to food with added value.

Edible beef skin is consumed regularly in African and Caribbean communities and is commonly known as Kanda or Kpomo. According to census data, between 2014 and 2018, 1.8 million people from Sub-Saharan Africa live in the United States. Approximately 10,000 of these immigrants live in Oklahoma and almost 210,000 in the state of Texas.

Traditionally, Kanda is made by taking a raw and unprocessed beef hide and applying a flame or high-heat source to the hair side of the hide. Once the hair is removed and burned off, it is then cleaned, packaged and kept cold until sold to the retailer or end consumer.

Kanda is prepared in several different ways but most commonly as a hot dish cooked in a flavorful sauce, like a stew and is usually served with rice.

Imported edible beef skin is available in African and Asian food stores across the United States, but their sources are usually dubious and mysterious, subjecting their consumers to potential health issues. Prior to work at FAPC, hides were considered as “inedible” material, and it was illegal to sell and process hides for human food consumption in the U.S.

FAPC specialists facilitated microbial testing and created a food safety plan in proving hides could be processed safely and legally. In turn, FAPC received the unprecedented, first-ever policy of no objection from the USDA-Food Safety and Inspection Service for developing, processing, labeling, marketing and entering commerce of edible beef skin.

FAPC specialists have been working with the client with various equipment test trials to make the process more efficient and profitable as the manufacturing process is commercialized.

In addition, Marel, a large food equipment manufacturer, showed interest in the project and donated a skinning machine, valued at more than $23,000, to FAPC for processing Kanda.

Thousands of pounds have been produced in FAPC’s pilot plant in 2020 for test marketing purposes and have been sold under the KandaKpomo label to three Asian and African retail stores in Oklahoma, one store in Dallas, Texas, and a small amount across the country through internet sales. As a result, the stores all are demanding more and cannot keep the product in stock.

The project will continue in 2021 with the goals of providing hands-on meat production training to students, making the manufacturing process more efficient, adding value to hides, eliminating the burden and cost of hide removal to the processor and providing dollars back to the processor.

- Food Processing - ‘Meating’ Essential Processing Needs

Changes have been realized on a global scale in 2020. As consumers learn to adapt and adjust to the outcomes of the pandemic, producers and workers in the meat industry especially have been impacted.

Sourcing from large meat packers has become the normal and usual way in which the large retail grocers have met the consumer demands for wholesome, excellent quality and reasonably priced meat products. The pandemic changed that because of reduced labor availability and changes in work practices among large packers. The meat supply was almost immediately affected.

Additionally, in the last several years, Oklahoma has experienced a reduction in meat processing facilities for many reasons. The local plant closures and the large plant production interruptions resulted in livestock that could not be harvested, meat that could not be processed, and consumers who could not locate and purchase meat.

The meat processing industry has turned to FAPC for assistance, and as a result, the center has been a critical component to help the industry cope with the changes.

Oklahoma’s meat processing plants are being inundated with harvesting and processing requests, and many are booked out for two years. Consequently, many producers are calling FAPC for assistance.

Although FAPC is not meant to compete with meat processing plants around the state, the center is helping to fill the need due to the reduction of processing capabilities in Oklahoma. FAPC’s meat pilot plant is heavily engaged with custom processing and is not showing any signs of slowing down.

In addition, individuals are coping with shortages by considering the pursuit of their own ventures in the meat processing industry. These ventures include the direct purchase of beef from producers and processors, as well as developing new meat processing establishments.

The state offered an incentive through the Federal Coronavirus Aid, Relief and Economic Security (CARES) Act Fund. State leaders identified $10 million to be made available as grant funds for the Food Supply Stability Plan for Oklahoma Meat Processors through the Oklahoma Department of Agriculture, Food and Forestry. The funding is to expand or upgrade existing facilities for increased outputs and efficiencies.

To help with the newly increased public interest, FAPC developed new meat processor resources to help individuals succeed, as well assisted applicants with business plans and facility and equipment purchases, and provided educational sessions to instruct and assist in learning.

But, because facilities and equipment are only part of the need, the Oklahoma Secretary of Agriculture and the Oklahoma Department of Career and Technology partnered in a plan to train skilled employees for these expanded and remodeled facilities.

FAPC is working with CareerTech to develop a curriculum with multiple comprehensive learning modules and avenues for delivery. The center will participate in a direct working collaboration with CareerTech to provide workshops to train individuals in the technology and art of animal harvest at FAPC’s meat processing plant.

These projects are just a few examples of how FAPC’s processing facility was designed with the needs of the Oklahoma food products industry in mind and, therefore, fits all levels of the industry. In addition to meat processing, the value-added one-of-a-kind center has processing expertise and capabilities in cereal grains, baked goods, and fruit and vegetable products.

- Food Safety, Quality Management and Sanitation - Joining Forces to Support the Food Industry

Delivering a product that not only is of a consistent quality but also safe for consumers is a high priority for the food industry. FAPC has expertise in food safety, quality management and sanitation practices to meet the needs and demands of the food and agricultural industries.

In 2020, FAPC partnered with the Oklahoma Small Business Development Centers to hire Stephanie Baker as a quality management specialist to lead and manage quality, food safety and security programs for the Oklahoma food industries, as well as best manufacturing practices for product outputs and employee safe health practices.

Food safety and quality management system certifications are an essential element required by many distributors and needed to launch a food manufacturer into an expanded market.

Global Food Safety Initiative standards focus and organize each facility’s existing processes and procedures in to a logical and comprehensive system. In addition to the global standards, the implementation of regulatory requirements are the foundation to a successful business operation.

Baker’s goal is to connect with companies who are looking for assistance with preparing for their first food safety audit, starting a quality management-focused project, or are in need of technical or regulatory advice.

Also, as a part of the FAPC and OKSBDC partnership, James Arati joined the FAPC team in summer 2020 as a business development specialist. Prior to joining FAPC, he worked in a dual role with OSU Extension and OKSBDC in assisting the development of materials and advisement for agricultural and food businesses.

Arati will continue to serve a dual role for FAPC and OKSBDC. His expertise in working with local food enterprises and farmers markets will provide a necessary link for entrepreneurs to utilize resources available at FAPC.

He also will assist start-up and existing micro and small food enterprise clients to develop solutions within their markets and help clients to conduct food business assessments and feasibility studies and develop business plans and growth strategies.

Often, small business entrepreneurs, who have the desire to start food businesses, are filling the roles of accountant, human resources, engineer, product development, food safety, quality management, sanitation and, of course, operations managers all at the same time.

By joining food processing resources from FAPC with the business development resources from OKSBDC, both centers are able to better support entrepreneurial and small businesses in the state, specifically in the area of food safety, quality management and sanitation.

- Packaging and Labeling - Providing Online Training for the Food Industry

The mission of FAPC is to help discover, develop and deliver technical and business information that stimulates and supports the growth of value-added food and agricultural products and processing in Oklahoma. One way FAPC accomplishes this mission is to provide workshops, trainings and educational seminars to food entrepreneurs and businesses, many of which are presented in-house at FAPC.

However, 2020 brought many challenges and changes to not only the state’s food and agricultural industries, but also around the world. One of the biggest obstacles was how to communicate with others, and FAPC recognized the need to change the way it delivered workshops, trainings and educational seminars.

Although FAPC had been working toward additional training opportunities prior to 2020, the COVID-19 pandemic accelerated the need for online training for entrepreneurs and food manufacturers.

As a result, FAPC started developing online trainings for some of its specialized in-house workshops. One of the first online trainings launched was Understanding Food Labeling Regulations.

Proper packaging and labeling is critical to attract consumers, meet necessary regulations and be food safety compliant. The Food and Drug Administration and United States Department of Agriculture have certain labeling requirements food processors must use to communicate needed information to those using and purchasing food products.

Knowing the rules and regulations for correctly labeling a food product is extremely important for food manufacturers. The mandatory elements required on a food label has direct effects on the design and functionality of the packaging.

FAPC’s expertise in educating the rules, regulations and mandatory elements is conveyed in the newly launched Understanding Food Labeling Regulations online course.

In addition, having the option to take an online course has many benefits. Cost and time savings usually are the biggest advantages compared to attending a live training at a predesignated place. Employees do not have to travel, which means time spent away from the plant is minimal, especially during the COVID-19 pandemic. Also, employers do not have to pay for travel time to and from the training location or a hotel room if needed.

Online participants can start and stop the training at any time and can go back and watch course modules as often as they would like. Participants also can take the course on their own schedule and pace.

FAPC’s specialists spent hours translating the current face-to-face class materials to an online format, which includes participant interactive and visual learning activities.

Topics covered in the online Understanding Food Labeling Regulations training include, but are not limited to, the anatomy of a Nutrition Facts panel, mandatory label elements, allergens, claims and genetically modified ingredients.

For more information or to enroll in the course, visit Understanding Food Labeling Regulations.

- Regulations, Customer Requirements and Compliance - Meeting Food Industry Needs: A Win-Win Situation

The passing of the Food Safety Modernization Act in 2011 has led to an increase in requirements for preventive controls, as well as good monitoring and record keeping. A food safety plan is a must for all levels of the food industry, and third-party audit programs are being required by a greater number of wholesale and retail customers.

KiZE Concepts, an entrepreneurial start-up company that produces nutrition bars, has experienced this first-hand as it has grown from renting shared space in its infancy to owning its own approximately 7,500-square foot manufacturing facility.

The relationship between FAPC and KiZE Concepts began in 2011 when Jeff Ragan, founder of KiZE, attended FAPC’s Basic Training for food entrepreneurs. The center’s assistance throughout the years has included equipment evaluation, product technical assistance, food safety, shelf life and sensory analysis.

A more recent project involves helping the Oklahoma City-based company with continuous improvement strategies and meeting customer requirements and third-party audits under Safe Quality Foods, one of several Global Food Safety Initiative programs.

Because KiZE now sells products through major retail chains and has contracts for co-packed production, adopting an accredited GFSI program and implementing a solid Total Quality Management culture has become a customer requirement and paramount to the success of the business.

To address this need, a graduate student project was developed that focused on quality standards of the various nutrition bars produced by KiZE. The project includes detailed mixing studies, portioning control and packaging efficiencies. Additionally, review of monitoring procedures and record keeping are part of the graduate student’s research plan. The student also has helped KiZE implement its SQF program, resulting in a successful desk audit; a facility plant audit will occur in the coming months. This in-plant experience not only provides data for the graduate student’s master’s thesis but also provides the student with real-world experiences in preparation for a career after graduation.

With FAPC’s assistance, KiZE recently received a grant from the Oklahoma Center for the Advancement of Science and Technology to help KiZE continue to grow and thrive as a Made in Oklahoma company. The grant provides for continued work in the areas of product quality and production efficiencies as KiZE continues to develop new markets and garner more customers. The grant will offset a portion of a graduate student’s assistantship.

Complying with federal, state and local regulations, as well as customer requirements, can be complex and puzzling. FAPC can help food producers and processors put the puzzle pieces together through many of its services and trainings to include global food safety systems, produce safety alliance requirements, Hazard Analysis and Critical Control Points, internal auditing and preventive controls for human food/animal foods.

The partnership between FAPC and KiZE Concepts has been a win-win situation for the company and for the student, and serves as a good example of how FAPC can help with regulations, customer requirements and compliance.

- Sustainability and Environmental Concerns - Sustaining Food Needs through Technological Innovation

A sustainable food system is one that provides healthy food to meet current food needs, while maintaining healthy ecosystems that also can provide food for generations to come with minimal negative impact to the environment.

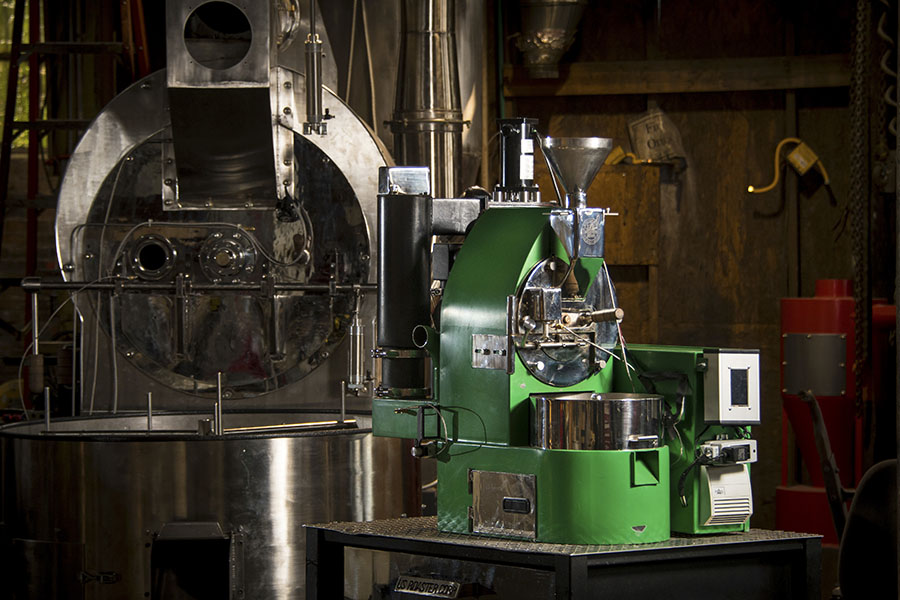

Technological innovations in equipment design aid food manufacturers in meeting sustainability objectives. One example is FAPC’s relationship with US Roaster Corp, an equipment manufacturer specializing in new roaster fabrication and rebuilding older roasters.

The relationship began in 2009 when the company began manufacturing its flagship roaster, The Revelation. This roaster is the world’s first industrial roaster to meet air emission standards of southern California. FAPC has continued to provide assistance aiding the company in its continuous improvement efforts

A more recent project involves helping the Oklahoma City-based company market a small, smokeless electric coffee bean roaster with cloud connectivity. The new mini coffee bean roaster design is based on The Revelation and can roast a batch of beans in 8 to 16 minutes, depending on the recipe. Target customers for this roaster include small coffee shops in the United States, China and Europe that want to add whole bean roasting to their operations.

This roaster is unique in that users can share roast profiles through the cloud. The mini Revelation allows users to connect a handheld electronic device to download and upload profile formulations with scalability from small to large roasters. Being able to make coffee exactly the same from user to user is only one benefit. The roaster also includes an interchangeable drum that is dishwasher safe, and because it is smokeless, it meets air quality standards anywhere in the world; there’s not another machine out there that can do all the things that this roaster can do.

With FAPC’s assistance, US Roaster Corp received a grant from the Oklahoma Applied Research Support Program within the Oklahoma Center for the Advancement of Science and Technology to improve the low-cost mini roaster. The grant is helping US Roaster Corp automate the controls of the mini, cloud-enabled Revelation; achieve full connectivity between the control system, handheld devices and the cloud; and establish a high-volume manufacturing line to meet current and forecasted demand for the new roaster. Working together with OCAST, OSU, industry partners and professional groups allowed US Roaster Corp to implement these goals.

The partnership between FAPC and US Roaster Corp has led to further connections with other OSU faculty, staff and students, giving the company additional valuable resources. As a result, US Roaster Corp has employed several OSU students, of which two have become full-time employees. Not only have sustainably objectives been accomplished through this relationship, but also business viability and personnel development have resulted.

Sustainable practices of food manufacturers are imperative in today’s food processing environment. The relationship between FAPC and US Roaster Corp is just one example of how FAPC can help processors examine their current practices regarding water usage, waste management and utilization, packaging selection, distribution options and other efficiencies within a company’s process flow.